They impact profitability, competitiveness, and strategic decision-making. By understanding and managing these costs effectively, businesses can thrive in a dynamic manufacturing environment. As can be seen from the list, the bulk of all conversion costs are likely to be in the manufacturing overhead classification. In a business that uses a high degree of automation, it is likely that manufacturing overhead costs will comprise the bulk of all conversion costs.

What Is Sustainable Marketing And Who Are The Key Players

- Therefore, the conversion cost per unit for the month was $6.80 per unit (calculated as $136,000 of total conversion costs divided by the 20,000 units produced).

- Second, not all your competitors will be as proactive as this.

- In a processing environment, there are two concepts important to determining the cost of products produced.

- In the long run, these minor changes can help you leave your competitors behind.

- In the Peep-making process, the direct materials of sugar, corn syrup, gelatin, color, and packaging materials are added at the beginning of steps 1, 2, and 5.

But it usually happens when business owners aren’t smart with the budget. Instead, they spend loads of money on campaigns that once worked for them. Or they don’t spend enough on campaigns that have the potential. You can have discussions with your marketing team regarding these non-profitable campaigns. First, it gives a boost to your campaigns that are already delivering.

Methods and Formulas

- In this section, we will delve into the concept of Conversion Cost Variance and explore how it can be measured and analyzed.

- As we discussed above, minor changes can make a big difference to your marketing campaign.

- You should also monitor and measure the performance of your campaigns and use data-driven insights to make informed decisions and adjustments.

- Calculating direct material cost involves multiplying the quantity of material used by its unit price.

- The factors that affect conversion cost and how to reduce it.

- By accurately calculating and managing these costs, companies can identify opportunities for improvement and make informed decisions about pricing, production, and process enhancements.

The conversion cost is reported in the financial statements as part of the COGS and the inventory valuation. The cogs is the cost of the goods that are sold during the accounting period, and it is deducted from the sales revenue to calculate the gross profit. The inventory valuation is the cost of the goods that are not sold and remain in the ending inventory, and it is reported as a current asset in the balance sheet.

Traffic, Conversion Rate, and Customer Acquisition Cost

- For example, you could say “Get instant access to our online course for only $49 (limited time offer)”, or “Download your free ebook and learn how to grow your business in 30 days”.

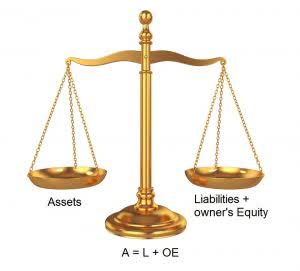

- Typically, it is equal to the sum of entity’s total direct labor cost and total manufacturing overhead cost.

- In this section, we will delve into the concept of the conversion cost ratio and its significance in cost accounting and management.

- The timing of advertisements has always been important, and it has been a concern for brands from the era of television commercials.

- If you are an accountant or finance manager, then knowing the conversion costs can help you accurately measure the production estimates.

- Conversion cost per unit is useful for measuring the efficiency and profitability of a production process, as well as for setting prices and budgets.

Based on the costs provided above, calculate the conversion of Company A. It excludes the salary of management, office staff, and other people who are not working directly with the products. Without proper control, it can lead businesses into financial ruin if not managed properly by management teams who know what’s best about how much each item should retail for. Collaboration plays a crucial role in achieving sales goals and fostering success within an… This means that you spent $10 to acquire each new customer for your course. In the next page, we will do a demonstration problem of the FIFO method for process costing.

Why Is Calculating CPC Key for Your Business?

The total conversion costs represent the sum of these two components, indicating the total expenses incurred by the company in converting raw materials into finished furniture products. Sometimes individuals become managers due to their knowledge of the production process but not necessarily the costs. Managers can view this information on the importance of identifying prime and conversion costs from Investopedia, a resource for managers. In the Peep-making process, the direct materials of sugar, corn syrup, gelatin, color, and packaging materials are added at the beginning Budgeting for Nonprofits of steps 1, 2, and 5. While the fully automated production does not need direct labor, it does need indirect labor in each step to ensure the machines are operating properly and to perform inspections (step 4). Conversion costs are also used as a way to measure the efficiencies in the production processes but they also take into account the overheads in the production process, which are not calculated in prime costs.

Discover conversion costs what a production management system is, its importance, functions,… She holds a Bachelor of Science in Finance degree from Bridgewater State University and helps develop content strategies. The iron, aluminium, and SBR tyres expenses are considered raw material charges in the example.

Conversion cost formula

Management needs to understand its costs in order to set prices, budget for the upcoming year, and evaluate performance. Managers can view this information on the importance of identifying prime and conversion costsfrom Investopedia, a resource for managers. Direct materials is the basic physical ingredient, matter or substance which CARES Act the company processes to make a salable product. Plastic, rubber, steel, iron, timber and many agricultural outputs like sugarcane, sugar beets, jute and cotton etc. are examples of direct materials that are processed to produce salable finished products.

And try to learn more about other marketing metrics as well. As we discussed above, minor changes can make a big difference to your marketing campaign. Use action words like “contact us” and “get a quote.” These words are direct, and that’s what call-to-action is about. Discover various types of production planning and control systems.

- The cost of conversion can vary depending on your industry, product, marketing strategy, and target audience.

- Conversion Cost includes direct labor and manufacturing overhead, covering all production expenses.

- By conducting a detailed analysis, companies can pinpoint areas of inefficiency or cost overruns and implement strategies to improve cost control and optimize the production process.

- Conversion costs are vital to be calculated by each companysince they are fundamental for making important business decisions and carryingout basic accounting tasks.

- Indirect materials, electricity charges and salaries of engineer and supervisor are all indirect costs and have, therefore, been added together to obtain total manufacturing overhead cost.

- They help the company to take important financial decisions and help them to bring efficiency to the production system.

For instance, in an automobile assembly line, the wages of assembly line workers and machine operators constitute direct labor costs. In the table above, various components of manufacturing overhead, such as rent, utilities, depreciation, maintenance expenses, and indirect labor costs, are listed along with their respective amounts. The total manufacturing overhead is obtained by summing up these indirect expenses. Hence, using conversion costs is an efficient way of calculating equivalent units and per unit costs rather than separately calculating direct labor and manufacturing overheads. Conversion cost is the cost the company spends on unusual expenses and direct labour when turning raw materials into finished products.